(Note from the author: This is a automated translation of the original German article)

For every experienced whiskey connoisseur it is almost banal

background knowledge: a whiskey must be matured in a wooden barrel

to become a whiskey at all. What sounds simple at first, has a

much broader horizon. Because who ever visited a warehouse, knows:

The variety of barrels is large. Different sizes, different types

of wood and a quantitatively hardly more tangible number of

prior use add up to this variety. In addition, anyone who has

ever compared supposedly identical single cask whiskeys knows that

even almost identical casks have different influences on the

distillate. So is each cask unique? Or are they all ultimately the

same? To find out more, I visited Dair Nua Cooperage, an

independent cooperage in Ireland, in December 2022.

Dair Nua Cooperage: An independent cooperage in Ireland

Dair Nua Cooperage has been operating as a separate company since

January 2022. The name is Irish. Translated, it means „new oak“

and makes a clear connection to the product. Its origins can be

found in the Nephin Distillery, which at its inception had a plan

to combine a distillery and cooperage under one corporate roof.

However, this plan did not work out. While the distillery is

currently still under construction, the cooperage eventually split

off. Dair Nua Cooperage was born as an independent cooperage in

the west of Ireland.

It is located outside Foxford, on the eastern shore of Lough Conn

in County Mayo. It’s half an hour from here to Ballina, home of

the Connacht Distillery. And half an hour south is the town of

Knock, famous for its basilica and the Shrine of Knock. Otherwise,

this part of Ireland is mostly rural. Lots of wide open country,

the large lake Lough Conn and behind it the mountain range Nephin

in the west.

What is a cooperage?

In a cooperage, new barrels are built and used wooden barrels are

repaired and reconditioned. This was once a common profession, as

wooden barrels served people for centuries as storage containers

for all kinds of items. This included wine, beer and all forms of

spirits. But storage habits changed, and materials other than wood

came along. Ultimately, in Ireland, the whiskey industry went

under. All factors that led to the cooper becoming a rare

profession.

Where are whiskey casks coming from? From the cooperage!

After a journey of almost four hours, I first drive through the

town centre of Foxford. The main road runs through the centre and

leads further north in the direction of Ballina. A few minutes

after the town centre I reach my destination in a side street. A

small commercial complex with simple halls awaits me. I park on

the street at the end of the cul-de-sac and step through an open

metal gate into the yard. The building on the right is divided

into two halls. The larger one is wide open to the side. Next to

it, wooden barrels are stacked up against the wall of the hall to

form a tall pyramid. They clearly signal what this is all about.

I look through a small window into an adjoining room. Two young

men are sitting in it and a woman is standing in the room. I wave

and go into the hall. The woman steps out of the room smiling and

immediately invites me into it. Inside, a heater is running at

full blast, providing a welcome warmth on this cold December day.

The woman is Annette Kearney, owner of Dair Nua, the independent

cooperage in Foxford, County Mayo, Ireland. In the room with her

are her two employees, Darren Leonard and Eoin Mangan. While

Darren is already a trained cooper, Eoin is an apprentice learning

the trade from him. This is the second time I’ve met the trio. In

doing so, our first encounter took place at the Whiskey Live trade

show in Dublin in June 2022. At that time, we initiated what we

did now: A guided tour through the barrel factory.

The cooper: A nearly lost profession

„Dair Nua Cooperage is the first independent Irish-owned cooperage in Ireland

for ages,“ reports Annette. „There aren’t any others. The only

other Irish coopers work for the big distilleries.“ Namely

Bushmills and Midleton. „The last outside of those two worked for

the Guinness brewery and stopped in the 1960s when beer was

henceforth stored in metal casks,“ she continues. „That’s why

Darran, and hopefully Eoin in the near future, are two of then

perhaps only four Irish coopers in total.“

As in so many specialist areas of whiskey production, the demand

for professionals is barely keeping pace with the growth of the

Irish whiskey industry. So, too, is the demand for barrel-making

experts. That’s why Darren learned his craft for four years from

2016 from two Scottish experts who traveled to the Emerald Isle

specifically for this purpose. Eoin now, in turn, is learning from

Darren, who has since moved on to become a Master Cooper. „That

would make Darren the youngest Master Cooper in Ireland,“ says

Annette proudly.

A tour of Dair Nua cooperage in Ireland

We now walk out of the small recreation room into the open hall.

Most of it is filled with barrels arranged in a neat block. „These

are barrels that were recently delivered from a distillery,“

Annette explains. They all need to be inspected, repaired if

necessary, and then refurbished.“ At the Cooperage, these whiskey

barrels begin their second stage of life. Annette explains:

„Brand new barrels start their life cycle with the first

occupancy. The most common are American oak barrels that first

hold bourbon whiskey. After their first emptying, these come to

Ireland and are refilled with Irish whiskey here.“ After quite a

few years, and often multiple occupancies of whiskey, the barrels

need to be refurbished in order to continue to be used for barrel

aging distillate. The same applies to wine barrels.

A cooper’s job: inspect, repair, rejuvenile whiskey casks

„The casks we receive are on average ten to twelve years old. But

some of them are as old as 30 or 40″, the owner of Dair Nua

Cooperage, the only cooperage in Ireland, knows. And further:

„They’ve then contained wine, bourbon, and whiskey for such a long

time that the wood is barely actively giving off flavor aromas.

Also, the barrel staves may be leaking or the barrel hoops loose.

This is where our work begins.“ Barrel staves are the name of the

rounded wooden boards that make up the barrel. The metal barrel

hoops, five in total, hold them together with pressure.

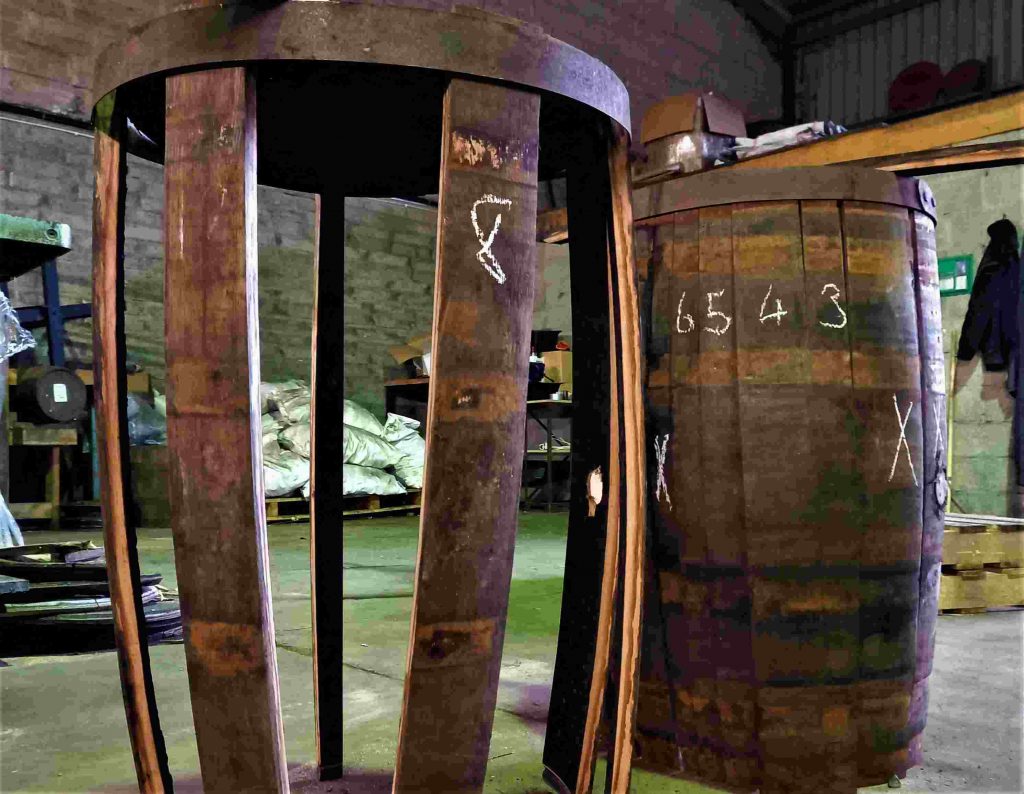

Repair works of cask at Dair Nua Cooperage in Ireland

First, cooper Darren and his apprentice Eoin inspect the barrels

and determine a need for repair. If there is one, they carry out

the necessary repairs. We go to the back work area of the hall.

There is a skeleton of a barrel from which they have removed most

of the staves and the barrel hoops. Only the uppermost barrel

ring still holds the whole construction together. This is a good

illustration of the constructional structure of a barrel. Darren

points out the different sizes of the staves. „If one is broken,

you have to find one that is identical in size. Or cut one to

fit,“ he reports. He numbers staves he removes from the barrel

with white chalk. That way, the expert can tell where it belongs

when he reassembles it. Once all the staves are intact and in

place, he refits the barrel hoops. To do this, he takes two tools

– a heavy hammer and a driver – and skillfully strikes

the metal hoops until they are in place. Finally, nothing moves.

Hoops and staves sit rock solid.

If the lid or end of the barrel is damaged, Darren and Eoin

repair them too or build a new one. To do this, the duo adjust the

staves at their end with special tools until the lid closes

tightly. „What excited me about the job from the start is that

it’s all handwork. And the tools are very

especially,“ says barrel craftsman Darren Leonard. He

demonstrates how he adjusts the narrow guide at the upper end of

the barrel with the so-called crozer so that the lid fits

correctly. This clearly shows why the profession of cooper

requires several years of training. The correct use of the

special tools and skilful precision work lead to the perfect

result.

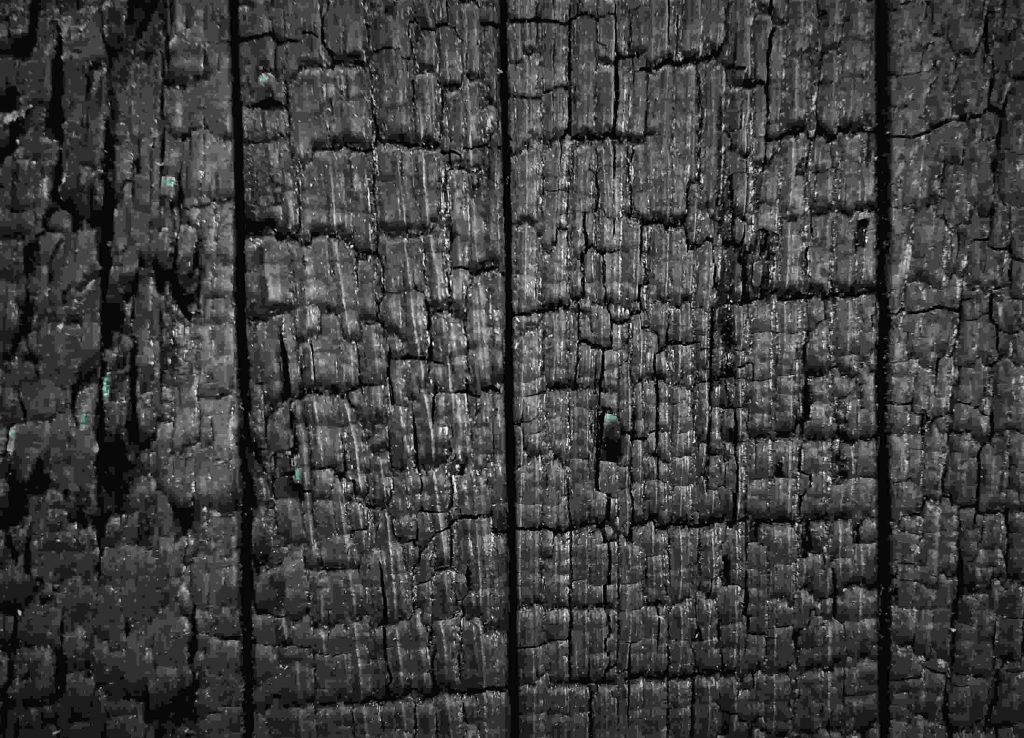

Rejuvenation: It all starts with de-charring

Once a cask is repaired, it rejoins the rest of the delivered

batch. This is now ready for reprocessing. For this, the barrel is

put into a machine which mills it out from the inside in

millimeter work. This way, the cooper removes a three-millimeterthick

layer of wood from which wine and spirits have drawn their flavors over decades.

„That used to be manual labor, too. But not a pretty one,“ Darren

laughs. The process also removes a light layer of char on the

inside of the barrel. That’s where the term de-charring comes

from. Then comes the second step of reprocessing. The barrel is

re-burned from the inside with a type of scorching. In the

process, a new, thin layer of charcoal forms on the inside of the

barrel.

Dair Nua Cooperage in Ireland: Re-charring turns old casks into new

Flaming, known as charring or re-charring in the case of used

barrels, is a standard procedure for wooden barrels. New and

reconditioned barrels are initially charred on the inside. The

process opens the wood pores and triggers certain chemical

processes within the wood cells. This results in the ability of

the wood to interact more strongly with the distillate. At the

same time, the typical wood aromas that connoisseurs find in

whiskey are created. For example, vanilla and caramel aromas are

created. The charring takes place in different intensity levels,

resulting in different degrees of charring. Four charring levels

are exhibited in the Cooperage. From a light level, called

toasting, to the strongest level, called alligator char. In fact,

the inside of the barrel of the Alligator Char is reminiscent of

the skin of the reptile.

Are all cask the same or unique?

„The cask is now ready to be used again. Basically, it is now

again very close to the level of a Virgin Cask, thus, a cask

before the first filling“, Darren concludes the tour. Now it

becomes clear that the variety of different types of casks

described at the beginning does not play too big a role for the

cooper’s work. Because the construction structure of the barrels

is always the same and the preparation process is identical. „In

their structure, all barrels are the same, no matter which wood,

no matter which barrel volume, and no matter what was stored in

them before,“ explains Darren, the budding master cooper.

„Of course, some types of wood are more porous and others are

harder. It’s important to keep that in mind when you’re working

on it so you don’t accidentally damage something. But at the end

of the day, the job is always the same.“

A cooper’s advice on how to store wooden casks correctly

We are back in the lounge and the small heater warms us up again.

I look outside where barrels are stored at the opposite end of the

yard. I ask how to store empty barrels optimally. To this Darren

again: „Ideally protected from rain. And lying down. So that no

standing water accumulates despite everything. Otherwise, the

climate in Ireland is ideal for long-term storage, even outdoors.

It doesn’t get too warm here. Too much sun and heat dry out the

wood and deform it.

Then a barrel can leak quickly,“ he explains. „That’s why it’s

best to store barrels filled with liquid rather than empty. As

long as the construction is under pressure, it doesn’t change.“

The future of Dair Nua Cooperage in Ireland

Dair Nua does not build new buildings. Annette reports: „We

started by trading barrels. My business partner Paul is located in

Bordeaux, so in the middle of a stronghold for used wine barrels.

Basically, however, we get barrels from everywhere.“ The cooperage

then prepares them and offers them to distilleries. „We get a lot

of requests for barrels. On the one hand, there is a shortage on

the market for bourbon barrels at the moment. On the other hand,

Irish distilleries are looking for extraordinary

casks to distinguish themselves on the market with a special

finish“, she describes the current demand. Many younger Irish

distilleries have used their first casks in recent years and

filled whiskey for the second time. With each additional bottling,

the need to repair and recondition these aging barrels increases.

That’s why Annette’s demand is constantly increasing. „We need

more people and more space,“ she says.

„We’re also working on automations like de-charring, so we want

to make manual labor more efficient with machines.“

She sees the automations themselves as a double-edged sword. The

profession of cooper was already threatened to die out and was

only recently revived with Darren and Eoin. However, to meet

demand and work economically, machine use is necessary. „The more

work that is done by machines, the less you need the expertise and

craftsmanship of the cooper. Yet that’s what we want to keep alive

and encourage,“ she says, describing the dilemma. That’s why

Darren, and later Eoin, should continue to train and ensure that

more and more young people pursue the profession of cooper. „I

would be happy if there were also female interested parties,“ says

Annette. „That would be an important concern for me.“