(Note from the author: This is an automated translation of the original German article.)

Although the Killarney Brewing & Distilling Company (KBD for short) has not yet distilled a drop of alcohol, it is currently one of the most promising projects on the Irish whiskey landscape. Since 2019, a short distance outside Killarney, their new distillery and brewery site has been under construction. Where Killarney Distilling Company is currently a construction site, the company plans to produce whiskey and beer made in Kerry for the first time in the near future. KBD is a parent company that includes the new Killarney Distilling Company and its sister, the Killarney Brewing Company.

The last one brews Irish craft beer and has been operating out of a small micro brewery in the inner city area since 2013. Behind the brewery is a founding team of three. While Tim O’Donoghue and Paul Sheahan are from Killarney, their partner Liam Healy is from Chicago. However, just as Tim and Paul have a soft spot for Chicago, Liam has always been drawn to Killarney, where he also has family connections. In the process, their craft beer has made it beyond Killarney’s borders in the years since its inception. The craft beer from the small brewery is also available in neighbouring towns and as far away as County Cork.

Killarney Distilling: A story of growing up

In contrast, their new project will not be small at all. The new KBD site, into which the distillery and brewery will move together, has a different dimension than their previous home. The Killarney Distilling site is in its final phase in autumn 2022. In the process, 24 million euros, mainly private capital from the founders and investors from the United States, went into planning and implementation. I have been able to see the new building from the main road for months, driving from my home in Tralee to Killarney. The size of the building is impressive, which initially contradicts the previous concept of a micro brewery. What is being built there, I asked myself regularly. After initial contact in the spring and several approaches for appointments over the summer, it finally fell into place at the end of September 2022. Their marketing manager Sadhbh invited me to visit the construction site and learn more about KBD and their plans.

The new gem on the Ring of Kerry

From Tralee it is only 30 minutes to Fossa, the small suburb of Killarney where the new site is located. This inconspicuous village has it all. A renowned German crane manufacturer is based here and ships container cranes worldwide. Fossa is also home to some of Killarney’s largest and most beautiful hotels. These are mainly located on the north shore of the beautiful Lough Leane, which the village overlooks. The Killarney National Park, the Gap of Dunloe and the highest mountains in Ireland form the majestic backdrop.

Through this setting, a few minutes outside Killarney’s bustling city centre, runs the N72 trunk road, dividing Fossa into north and south halves. The road is better known worldwide as the first section of the famous Ring of Kerry. This is where I now find myself on a sunny September afternoon. My destination, the Killarney Distilling site, can be seen from afar. Surrounded by green pastures, the huge new building stands out against the blue sky.

Striking architecture plays with modernity and tradition

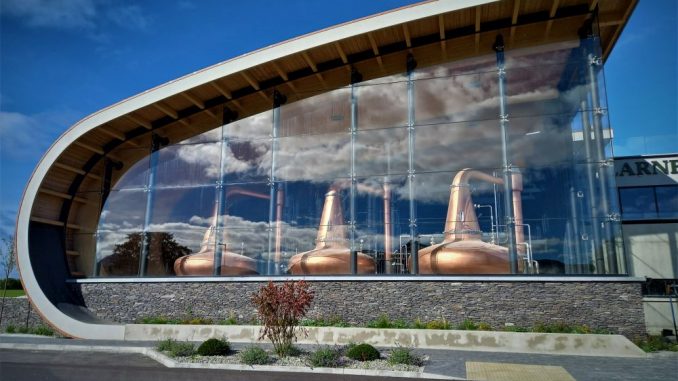

I park my car in the empty car park in front of the building. The border is newly laid out, the red sales labels with the plant names on the ornamental shrubs are still blowing in the shallow autumn wind. The flat entrance area in the middle of the building is crowned with the company name in matt grey. Above it, the glass railing of an open roof terrace is visible. Next to it on the left is the west wing of the building. The arch-like shape of its west wall and ceiling is striking. The futuristic architecture is strongly reminiscent of the newer Terminal 2 at Dublin Airport. The front side is glazed. Behind this reflective glass façade shine three brand new pot stills: the new distillery of the Killarney Distilling Company. Still a building site.

The front of the east wing is also glazed. Its architecture, however, is completely different from its counterpart. While the architecture of the west wing is modern, the east wing has a more traditional look. Grey stone walls, arched windows and a vaulted roof are reminiscent of a stable building. Stainless steel tanks can be seen behind the large windows. Again, this is where the brewery has found its new home.

Killarney Distilling: Gin production is (nearly) about to start

Sadhbh had organised an appointment for me with the two distillers Colm and Meadhbh. The last one now greets me kindly in the reception area. „Colm is still busy for a short while, I hope he will join us soon,“ she smiles at me. So we start off in Meadhbh’s realm first, „I’m a distiller in charge of the gin distillation.“ She briskly walks through a door and we cross the brewery in the east part of the building. A separate room at the end of the brewery houses the gin apparatus, a hybrid still with a capacity of 500 litres. The gin apparatus is small in relation to the huge building and at first glance seems lost in the large space. In style and size, the still is reminiscent of the apparatus at Glendalough Distillery, the small micro distillery in the Wicklow Mountains.

Having a glass on the construction site

„We haven’t started the real distillation yet, because we are still waiting for the official acceptance of the apparatus.“ Nevertheless, Meadhbh has a small sample of her skills for me: „We are allowed to distil very small amounts for test purposes.“ She pours a sip of gin from a sample bottle into a glass. „This is our Killarney Core Dry Gin. This will be our standard gin once we officially start production,“ she explains. „Also planned is a Killarney Poitín.“

Until now, the Killarney Distilling Company has marketed a gin distilled by third parties under its own label. They work together with a local beekeeper and the end product is Killarney Honey Gin. I also try a sip of this and can confirm: I am looking forward to the Core Dry Gin from Meadbhs Still. I ask them where the botanicals for the gin will come from. „We collect a few locally, but most of it we source through suppliers,“ she explains.

No whiskey or beer yet, but good food and amazing views

We continue walking through various corridors, Meadhbh always in front. Meanwhile, she tells us something about herself: „I’m from Cork. I’ve been in Killarney for a year now.“ Before that, she studied for a Master’s degree in Food & Beverage and worked for the multinational ABInBev in Belgium.

Finally, we climb a staircase and come to an anteroom adorned by a historic still. „This still still works, but is only used for decoration.“ She points to a stove flap at the front. „It is heated with classic fire,“ she smiles. A plaque identifies Friedrich Müller Apparatebau as the manufacturer. The four-digit postcode, also legible on the plaque, dates the still to before 1993, the year of the postcode reform in Germany.

600 curious guests

Behind the vestibule, a larger area opens up with a large bar in the centre. Cosy seating areas are set up around it. At the end is a glass front. Behind it, the blue sky shines and the mountains of Killarney form the panorama. The restaurant has been open since mid-September, and guests sit at the tables along the window side and enjoy food, drinks and the fabulous view.

On the other side of the room is a large, open kitchen. Busy cooks and waiters can be seen and the smell of food hangs pleasantly in the air. „We have a fully equipped bar and restaurant here,“ Meadhbh reports. This is going down well with the residents. „For months people have been asking when we would open the restaurant. And on the first day of opening, 600 curious guests came.“

Diversification targets tourists and locals

So the new Killarney Brewing & Distilling Company is not just about producing beer and spirits. The restaurant with its bar is only one part of the diversification that becomes apparent as we continue our tour. An event centre for events of all kinds with up to 200 guests is also being built in the complex. The restaurant’s kitchen will provide the catering for the event. In addition, another tap room for beer tastings will be connected to the brewery. „There will also be a small chocolate factory where children can let off steam while their parents taste beer and whiskey,“ Meadhbh smiles.

A closer look at the construction site

An inner wall of the restaurant is also glazed. Behind the panes is the open west wing and the view falls on the distillery. Stainless steel tanks are visible and at the left end the three gleaming pot stills. Before we go downstairs, however, Meadhbh first takes me up another floor. On the roof terrace, individual barrels are scattered around as bar tables. The rainwater of the last few days has collected on the lids and reflects the sun. It now warms our faces as we stare towards the mountains. The view is simply unique. „Up here we are building another extra bar for small events and tastings,“ Meadhbh explains.

We go down again and through more corridors Meadhbh takes me to the distillery. While reception and catering are already fully open, everything here is still a construction site. It is dusty, tools and building materials are lying around. We walk through a door and I have to bend down low, because a scaffold blocks half of the passage. Under the scaffolding we enter the main part of the Killarney Distilling construction site.

Production start by Christmas 2022

So far, I have been particularly impressed by the size of the building and the well thought-out gastronomic areas. Now my gaze falls on something I didn’t expect: Column Stills. The four slender columns rise almost to the ceiling. Meadhbh catches my astonished glance. „Yes, we will produce our own grain whiskey and also distil the neutral alcohol for our gin ourselves,“ she explains. She then reaches for her mobile phone, „I’ll see how far Colm is. This is his area here.“ One phone call later, Colm is on his way. While we wait, another employee enters the Killarney Distilling site. Meadhbh greets him and introduces him to me as Paraic. „Paraic is the project manager on the site and our go-to guy,“ she says, smiling at him. „Firefighter,“ he says himself. „There’s always a fire somewhere and I have to put it out.“ Paraic laughs.

He points at a filter press on the wall. In future, the mash will be filtered here instead of in a Lauter Tun. The wooden curve of the wall and ceiling arches above it. „No electricity connections,“ Paraic says. „They told me to plug in the filter press, yet there are no electrical outlets in that area.“ Such problems need to be solved before production can begin. Says Meadhbh: „We are confident that we will have all the work done before Christmas and can start distillation.“

Pot Still Whiskey, Malt Whiskey and Grain production

Shortly after Paraic has left again to put out another fire, Colm enters the Still House. The young man quickly brings some documents to the square box that will soon house the control centre for the distillers. „This will be the command centre. It will be completely encased in copper on the outside,“ Colm beams. Again I am amazed and Colm smiles. Then he gives me some key data on the future production.

„We don’t have official acceptance yet, so of course all the data is not verified yet,“ he begins. „We process the grain with a hammer mill. Two tonnes are then processed into mash. Then they go into the filter press. We will primarily produce pot still whiskey. That’s why fermentation is important for us. We have the possibility to precisely control the temperatures during fermentation. This is important for the production of pot still whiskey,“ Colm explains in detail. „Normal fermentation times are 24 hours. But if you allow a longer fermentation, new substances develop that can later be found in the taste of the distillate. That’s why we will ferment between 72 and 120 hours.“

Vintage Pot Still mash bills

Colm drew his knowledge of pot still whiskey production from his previous stations. Originally from Dingle, he began his career in 2018 at the Dingle Distillery. In 2020, he moved to the east coast of Ireland. To Boann Distillery. „There I was involved with the distillation of vintage mashbills,“ he looks back. In an interesting project in cooperation with the historian Fionnán O’Connor, the Boann Distillery produced various pot still whiskeys based on historical recipes. Will one or the other of these recipes be distilled in Kerry in the near future? „Of course!“ laughs Colm.

For distillation, he has three copper stills from the Italian manufacturer Frilli at his disposal. Their capacities are 12,000 litres, 8,500 litres and 7,000 litres. Both double and triple distillation are envisaged. „Together with the column stills, we can produce up to one million litres of pure alcohol (LPA) a year,“ says Colm. The distillery team consists of Colm and Meadhbh, as well as Kerr, the Master Distiller. Once production starts, two more employees will be needed for the distilling process.

We leave the Still House and step outside. A path leads along the side of the modern building. Behind it is another complex of buildings: offices and warehouses. Here, too, everything is still under construction. A worker sits on the floor and cleans paint from a brush under a water hose. In a large hall we meet Kerr, the Master Distiller of the Killarney Distilling Company. Colm says goodbye to be able to devote himself to other tasks. Now it is Kerr who gives me further insights.

Future plans

„This is our vatting hall,“ he explains. Huge tanks stand in one side of the hall. Kerr points to open pipes coming out of the wall. „From there, the distillate comes out of the stills, is caught here, collected and eventually put into IBCs (note: intermediate bulk containers) or directly into barrels.“ For storage, a warehouse is being built in the adjacent building. „There we want to store the things that we want to use again quickly. Everything else goes to warehouses like Stafford’s in Wexford where it stores for longer,“ Kerr says. Then he points to a large bare wall, „That’s where the casks for our Cask Programme go.“ This is the Cornerstone Cask Society, a programme for people who want to buy their own cask of raw Killarney Distilling Company spirit and mature it into malt whiskey or pot still whiskey.

Cornerstone Cask Society, markets and the first release

But that is still up in the air. „We are currently working on our second limited release,“ says Kerr. This is a whiskey bought in from a third party and sold as a set under the Killarney label together with a limited beer from the neighbouring brewery. The first edition appeared in 2021. „After that, our Core Blend will appear. Initially, of course, with bought-in whiskeys, but later with our own. Here, we will be careful to ensure that there are no major differences in taste when we finally blend our own whiskeys,“ he continues. Malt whiskeys and pot still whiskeys with different ages will also appear. But single grain whiskey is also to complement the portfolio.

The Killarney Distilling Company wants to grow first in its home market of Ireland. Given the size and planned output, this is a modest goal. But of course the path towards the US market is set. „We’re all a bit Chicago-crazy here,“ Kerr laughs, alluding to the founding team around Chicagoan Liam. Besides, US-Americans are one of the largest groups of visitors to the Kerry tourism centre. Especially in and around Killarney. „Killarney is Ireland’s second largest tourism destination after Dublin,“ says Kerr. „And we’re right in the middle of it.“

My sincere thanks to Meadhbh, Colm and Kerr for their time and site guidance. I will be following and reporting on further developments at the Killarney Distilling site over the coming months.